5 Unique Features of the Best Pouch Filling Machine You Need to Know

In the rapidly advancing world of packaging technology, the Pouch Filling Machine stands out as an essential asset for manufacturers seeking efficiency and reliability. As businesses strive to meet growing consumer demands for convenience and sustainability, understanding the unique features of a high-quality pouch filling machine becomes paramount. This blog will delve into five distinctive attributes that set the best pouch filling machines apart from the rest, providing insights into their functionality and the benefits they offer.

From enhanced speed and precision to advanced automation capabilities, these machines not only improve production efficiency but also contribute to product integrity and customer satisfaction. Join us as we explore these remarkable features and uncover why investing in a top-tier pouch filling machine can be a game changer for your packaging process.

Key Indicators for Evaluating Pouch Filling Machine Quality in the Market

When evaluating the quality of pouch filling machines in the market, several key indicators can help buyers make informed decisions. One of the most critical aspects is the machine's accuracy in filling pouches. A high-quality pouch filling machine will maintain consistent volume control, ensuring that each pouch is filled to the desired weight without wastage. This precision not only improves product quality but also enhances customer satisfaction, making it a vital feature to consider.

Another important factor is the machine’s speed and efficiency. The best pouch filling machines are designed to operate at high speeds without compromising on accuracy. This capability is essential for manufacturers looking to optimize production throughput. Additionally, ease of use and maintenance play a significant role in determining the machine's overall quality. A user-friendly interface and easy access to components for cleaning and repairs can significantly reduce downtime, making these features crucial for smooth operation in any production environment.

Understanding the Different Types of Pouch Filling Machines Available

When exploring the world of pouch filling machines, it's essential to understand the different types available, as each is tailored to meet specific production needs. These machines can generally be categorized into three main types: vertical form fill seal (VFFS), pre-made pouch fill seal (PFS), and rotary pouch filling machines. Each type presents unique advantages and operational efficiencies that can significantly influence productivity.

Vertical form fill seal machines are widely used in the packaging industry due to their capability to create pouches from rolls of film, fill them with product, and then seal them all in one continuous process. This type is particularly beneficial for high-throughput operations, as it minimizes handling time and reduces material waste. Alternatively, pre-made pouch fill seal machines offer flexibility, as they accommodate various pre-formed pouches, allowing for diverse packaging designs while maintaining speed and accuracy in the filling process. Rotary pouch filling machines, on the other hand, excel in speed and are often employed in high-volume production environments, as they efficiently cycle through multiple pouches per minute.

By understanding these types of pouch filling machines, manufacturers can make informed decisions regarding equipment that best aligns with their operational goals, enhancing overall productivity and ensuring product integrity. Each machine has features that cater to specific needs, from speed and efficiency to versatility in packaging styles.

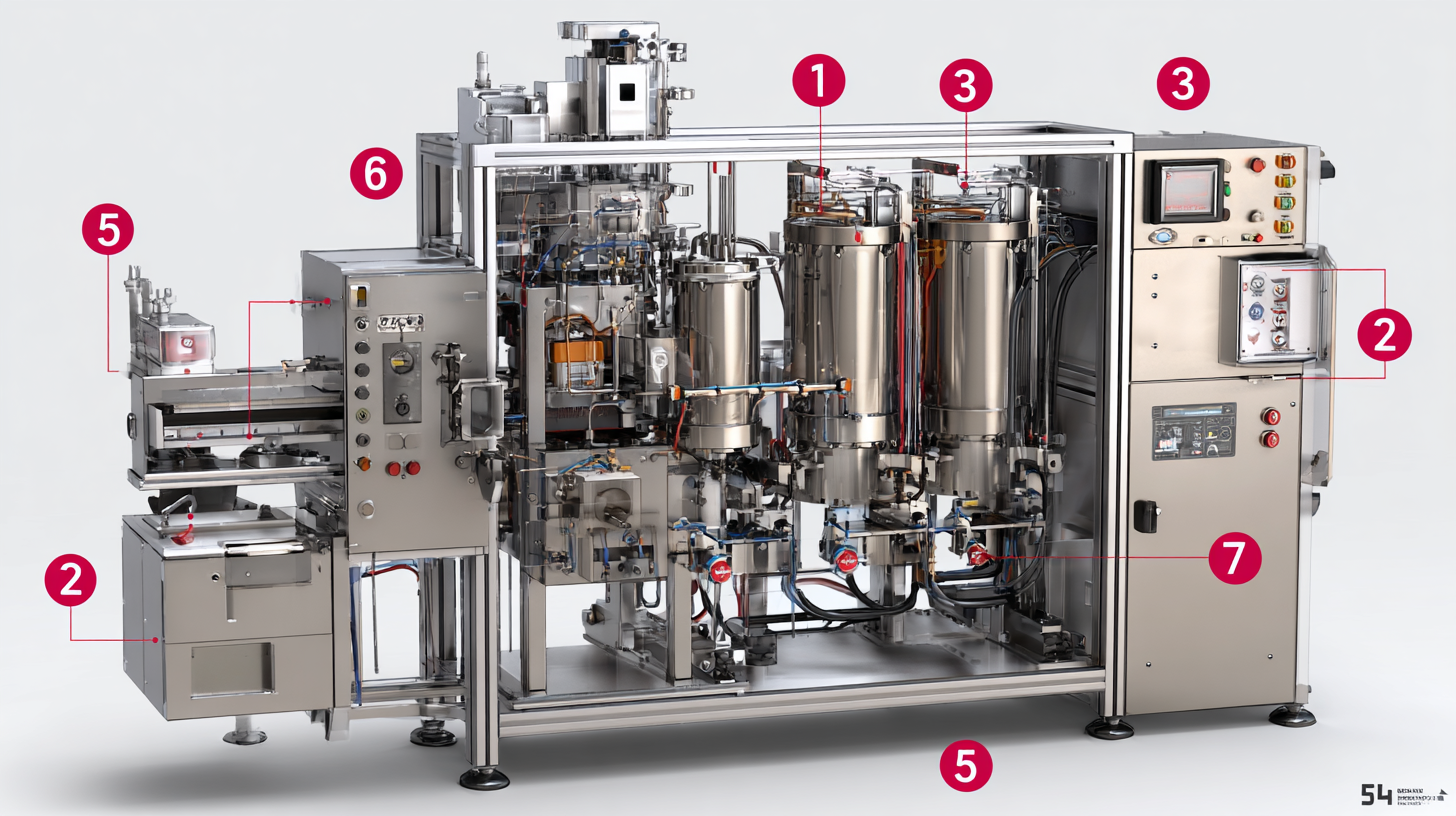

5 Unique Features of the Best Pouch Filling Machine

Top-Specified Features for Enhanced Efficiency in Pouch Filling Equipment

When it comes to maximizing efficiency in pouch filling equipment, understanding the key features of the best machines is crucial. One of the standout specifications is the machine's filling accuracy. High-quality pouch filling machines are equipped with advanced sensors and calibration systems that ensure precise measurement of materials, reducing waste and increasing product consistency. This level of accuracy is essential not only for meeting production quotas but also for maintaining customer satisfaction with consistently filled products.

Another important feature is the speed and automation capabilities of the filling machine. The best pouch filling machines can operate at impressive speeds while minimizing manual intervention. This automation not only streamlines production processes but also allows for better allocation of human resources to more critical tasks. Enhanced speed translates to higher output rates, making it a vital consideration for manufacturers looking to scale their operations effectively. Additionally, modern pouch filling machines often come with customizable settings, enabling users to tailor the filling process to specific requirements, further optimizing efficiency.

Industry Trends: Innovations in Pouch Filling Technology for Better Performance

In the fast-evolving world of packaging, innovations in pouch filling technology are setting new benchmarks for performance and efficiency. Manufacturers are increasingly adopting smart automation systems that enhance speed and accuracy, reducing downtime and waste. These advancements not only streamline the filling process but also improve consistency, a key factor in maintaining product quality across large batches.

Tip: When considering a pouch filling machine, evaluate models with integrated sensors that monitor fill levels and adjust automatically. This feature can significantly cut down on material wastage and ensure that each pouch is filled to the same precise standard, ultimately saving costs in the long run.

Another trend gaining traction is the use of eco-friendly materials and designs. Many companies are now investing in machines that accommodate recyclable or biodegradable pouches, aligning their operations with sustainability goals. As consumer awareness about environmental impacts grows, brands that prioritize eco-friendly practices can enhance their market appeal.

Tip: Look for manufacturers that offer flexible machines capable of handling various pouch sizes and materials. This versatility not only accommodates changing market demands but also positions your business as a forward-thinking player in the industry.

Key Metrics to Determine Supplier Reliability in the Pouch Filling Sector

When selecting a supplier in the pouch filling sector, understanding key metrics of their reliability is essential. One vital metric is their production capacity. A reliable supplier should comfortably meet growing demands without compromising quality. Evaluate the machinery they employ; advanced and well-maintained equipment indicates a supplier’s commitment to efficiency and precision in the packaging process.

Another crucial element is quality control practices. It’s imperative to assess how the supplier manages quality assurance, including their adherence to industry standards and certifications. A robust quality management system not only enhances product consistency but also minimizes the risk of defects. Additionally, customer feedback and references can provide insight into a supplier’s performance history. Trustworthy suppliers often have positive testimonials, reflecting their ability to deliver reliable results consistently, ensuring your products are packaged correctly and delivered on time.