How to Choose the Right Sachet Packing Machine for Your Business Needs?

Choosing the right Sachet Packing Machine is crucial for many businesses. The market offers various models, each tailored for specific needs. Finding the best fit can seem overwhelming, especially with many options available.

Consider your product type first. Some machines handle powders well, while others excel with liquids. This distinction can significantly impact efficiency and quality. Pay attention to speed as well. A machine that is too slow may hinder your business growth. Think about your production goals.

It's essential to weigh your budget against the required features. Cheap options may save money upfront but might lead to costly downtime. Exploring different brands can highlight varying reliability. Also, take into account the machine's maintenance needs. After all, investing in a Sachet Packing Machine is a long-term decision.

Understanding the Different Types of Sachet Packing Machines

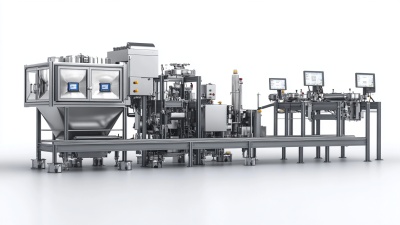

When selecting a sachet packing machine, it’s crucial to understand the different types available. Sachet packing machines come in various forms, including horizontal, vertical, and multi-lane options. Each type has its unique advantages and is suitable for different products. For instance, horizontal machines are effective for packaging flat products, while vertical machines are ideal for powders and granules. According to a recent industry report, the global sachet packaging market is projected to reach USD 20 billion by 2027, highlighting the growing demand for efficient packing solutions.

Tips: Consider the speed requirements for your production line. Some machines can produce up to 300 sachets per minute. This could be overkill for smaller businesses. Evaluate your needs carefully to avoid unnecessary costs.

Multi-lane sachet packing machines are another option. They increase output by packing multiple sachets at a time. However, they can be more complex and costly to maintain. An industry study found that about 30% of businesses faced operational issues when implementing these machines. Reflect on whether your team can handle such complexity. Simplifying your process might yield better consistency.

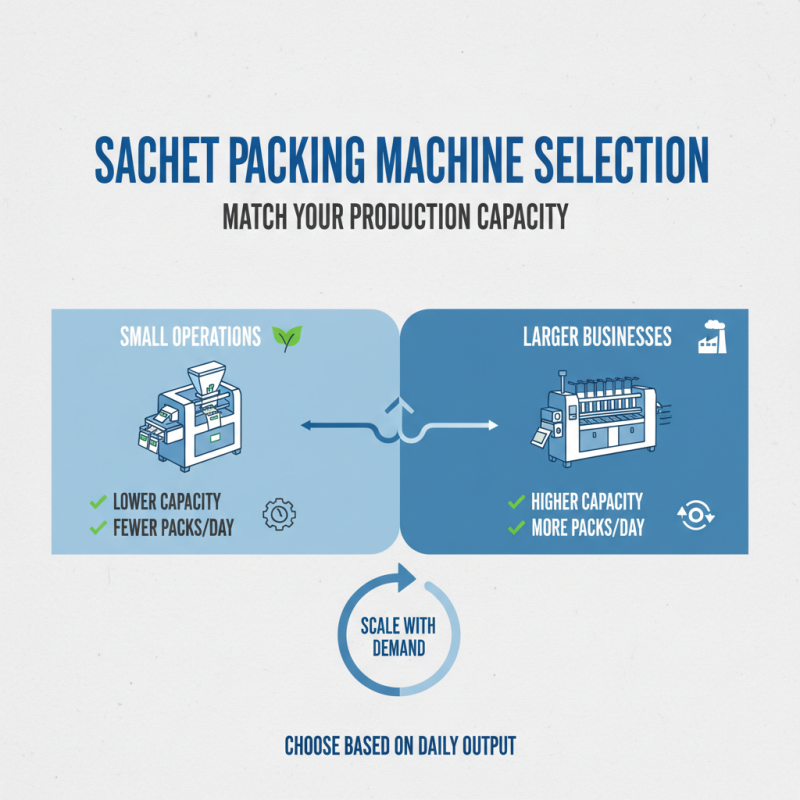

Assessing the Production Capacity Required for Your Business

When choosing a sachet packing machine, assessing your production capacity is crucial. Understand how much product you need to package daily. This will guide you in selecting a machine that meets your business demands. A small operation may only require a lower-capacity machine, while larger businesses might need higher speeds.

Consider your space. A compact machine might fit perfectly in a small area. However, if you have room, a more robust unit may save you time. Keep in mind that efficiency can vary. Sometimes, machines promise high outputs but require frequent maintenance.

**Tips:** Always check the machine's specifications before purchase. Make sure it aligns with your production goals. It's wise to ask for a demonstration too. Look for machines that offer easy adjustments, as your needs may change.

Reflect on your growth plans. If you expect to scale up, opt for a machine with flexible capacity. Be prepared to reassess your choices. The right machine should not only fit today’s needs but also adapt to future demands.

Evaluating Key Features and Specifications in Sachet Machines

When selecting a sachet packing machine, it's essential to evaluate key features and specifications. This process can significantly impact the efficiency of your production line. Industry reports indicate that about 40% of businesses struggle with continuous operation due to inadequate machinery. Therefore, understanding the capabilities of various options is crucial.

Look for machines with adjustable speed settings. This feature allows you to modify packaging speed based on demand. A study by Packaging Machinery Manufacturers Institute reveals that machines with speed variations can improve output by up to 30%. Also, consider the sealing technology. It should cater to the materials you pack. Different materials require specific sealing techniques for optimal results.

Moreover, the size of sachets matters. Machines that accommodate multiple sizes offer flexibility for changing market demands. Many companies underestimate this aspect, leading to inefficiencies. Durability is another critical factor. Machines that frequently break down can cause significant production delays. It's important to analyze both the initial cost and the long-term operational costs. A machine that seems cheaper may lead to higher maintenance expenses. Hence, thorough analysis is key.

Key Features in Sachet Packing Machines

Budget Considerations: Cost vs. Quality in Purchase Decisions

When considering a sachet packing machine for your business, budget is a crucial factor. You might be tempted to go for the cheapest option. However, this could be a mistake. Low-cost machines often lack durability and efficiency. They can lead to higher operating costs over time. A cheap machine may mean frequent repairs or replacements. This can affect your productivity significantly.

Balancing cost and quality is vital. Invest in a machine that suits your production needs. Higher quality machines often come with better support and warranties. They may have advanced features that save time and resources. But remember, a very high price tag doesn't always guarantee exceptional quality. Research is key. Compare different options and gather user reviews.

Think about the long-term implications of your purchase. Will a mid-range machine serve you better than a low-cost one? Would the upfront savings justify future struggles with inefficiency? Reflecting on these questions can guide you in making the right decision. Always weigh the real cost versus the initial price. Quality often leads to better performance and lower overhead costs.

How to Choose the Right Sachet Packing Machine for Your Business Needs?

| Feature | Budget Range ($) | Quality Rating (1-10) | Production Speed (units/min) | Maintenance Frequency (months) |

|---|---|---|---|---|

| Basic Model | 1,000 - 3,000 | 5 | 20 | 12 |

| Mid-Range Model | 3,500 - 7,000 | 7 | 30 | 8 |

| High-End Model | 8,000 - 15,000 | 9 | 50 | 6 |

| Custom Model | 15,500+ | 10 | 100 | 4 |

Identifying Reliable Suppliers and After-Sales Support Options

When selecting a sachet packing machine, finding reliable suppliers is crucial. Look for companies with a strong reputation in the industry. A good supplier will provide detailed product specifications. They should be clear about machine capabilities and limitations. Ask for references from other customers. Reach out to them for feedback. This step can help build trust.

After-sales support is equally important. Your machine will need maintenance and parts replacement over time. Ensure the supplier offers robust support services. Inquire about the availability of spare parts. Quick access can minimize downtime. Training for your staff may also be necessary. Consider if they provide this service.

Finally, reflect on the long-term relationship with suppliers. Building a connection can lead to better deals in the future. Communication is key. Regular check-ins can prevent issues from escalating. Choosing the right supplier is a process. It requires diligence and effort, but the rewards can significantly benefit your business.

Related Posts

-

Mastering the Art of Sachet Packing: A Comprehensive Guide to Optimizing Your Efficiency

-

How to Choose the Best Sachet Packing Machine for Your Business Needs

-

Exploring Sachet Filling Machines Features and Applications for Optimal Production Efficiency

-

Sachet Filling Machine Innovations Transforming Global Packaging Solutions

-

How to Choose the Right Sachet Packing Machine for Your Business Needs

-

10 Innovative Features of the Best Automated Packaging Machine