10 Innovative Features of the Best Automated Packaging Machine

In today’s fast-paced manufacturing landscape, the importance of efficiency and precision cannot be overstated, particularly in the packaging sector. The global automated packaging machine market is projected to reach approximately $60 billion by 2027, highlighting the growing reliance on automation to streamline processes and reduce operational costs. Innovations in technology have led to the development of advanced automated packaging machines that not only enhance productivity but also minimize human error and waste. These machines are designed to handle a diverse range of products, fulfilling the increasing demand for customized packaging solutions. As businesses strive to meet consumer expectations for speed and sustainability, understanding the innovative features of these automated packaging machines becomes essential for maintaining a competitive edge in the industry.

In today’s fast-paced manufacturing landscape, the importance of efficiency and precision cannot be overstated, particularly in the packaging sector. The global automated packaging machine market is projected to reach approximately $60 billion by 2027, highlighting the growing reliance on automation to streamline processes and reduce operational costs. Innovations in technology have led to the development of advanced automated packaging machines that not only enhance productivity but also minimize human error and waste. These machines are designed to handle a diverse range of products, fulfilling the increasing demand for customized packaging solutions. As businesses strive to meet consumer expectations for speed and sustainability, understanding the innovative features of these automated packaging machines becomes essential for maintaining a competitive edge in the industry.

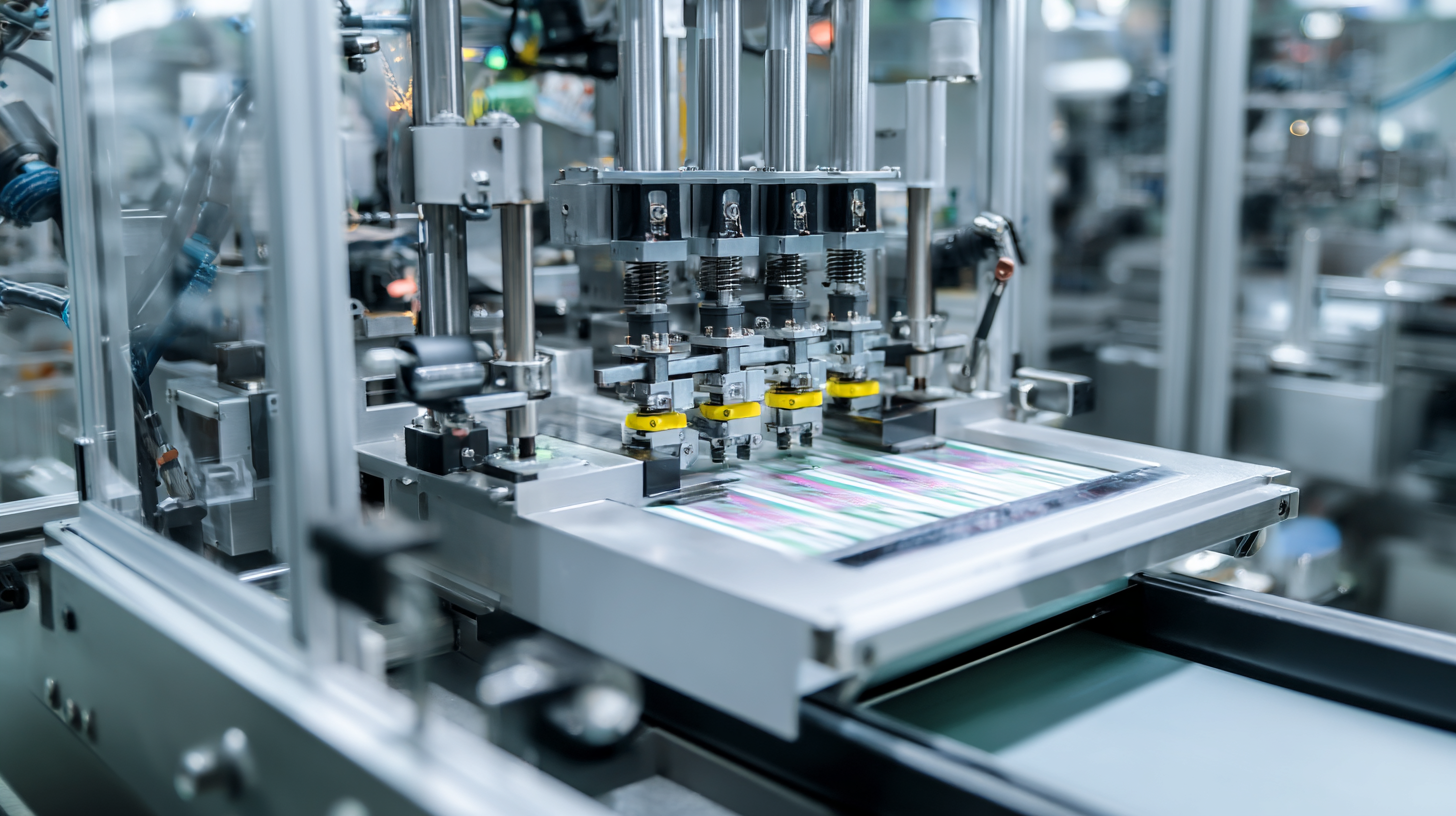

Revolutionizing Efficiency: Speed and Precision in Automated Packaging

Automated packaging machines are rapidly transforming the landscape of manufacturing and shipping industries, enhancing efficiency through speed and precision. According to a report by Future Market Insights, the global automated packaging market is projected to reach USD 80 billion by 2026, driven by advancements in technology and the increasing demand for faster production lines. These machines utilize sophisticated algorithms and sensors to ensure packaging is consistent and accurate, minimizing waste and reducing operational costs. In fact, companies employing automated solutions can achieve packaging speeds up to 200 packages per minute, far surpassing manual processes.

The precision of automated packaging machines not only boosts productivity but also ensures product integrity. As noted by a study from the Institute of Packaging Professionals, automation reduces human error, which can lead to costly mistakes and product losses. With the implementation of robotics and smart technology, manufacturers can track and adjust parameters in real-time, allowing for high accuracy in packaging sizes and weights. The integration of these innovative features is not only a step towards increased efficiency but also enhances overall supply chain reliability, aligning with the industry's shift toward sustainable packaging practices that prioritize both speed and environmental considerations.

Smart Integration: How IoT Enhances Packaging Operations

The integration of IoT in packaging operations marks a significant transformation in the packaging industry. By leveraging IoT technologies, companies can now monitor and optimize their packaging processes in real-time. According to a recent report, IoT-enabled packaging solutions can enhance operational efficiency by up to 30%, reducing waste and downtime. This is achieved through smart sensors that provide valuable data on inventory levels, equipment performance, and environmental conditions, allowing for proactive decision-making and resource optimization.

Moreover, the adoption of AI alongside IoT is advancing the capabilities of automated packaging machines. These machines can rapidly adapt to varying production demands, ensuring consistent output quality while minimizing human intervention. A study indicates that implementing AI-powered IoT systems can lead to a 25% increase in productivity. Additionally, blockchain technology is being integrated to enhance traceability and security in packaging, offering consumers greater transparency about product origins and sustainability practices. Collectively, these innovations are driving the industry towards a smarter, more efficient future.

Sustainability Matters: Eco-Friendly Features of Modern Machines

In today's packaging industry, sustainability has emerged as a pivotal focus, driving innovations in automated packaging machines. Modern machines are designed with eco-friendly features that not only meet environmental standards but also cater to the growing demand for sustainable practices. One key advancement is the integration of biodegradable materials, allowing companies to reduce their reliance on traditional plastics. Manufacturers are now producing packaging that can decompose naturally, thus minimizing waste and supporting a circular economy.

Moreover, energy efficiency is a hallmark of contemporary automated packaging solutions. By utilizing advanced technologies such as servo motors and energy-efficient controls, these machines significantly lower energy consumption during operation. Additionally, many models are designed to optimize packaging materials, minimizing excess while ensuring product safety.

This optimization not only reduces material waste but also cuts down on transportation costs, further contributing to a more sustainable supply chain. As the industry continues to evolve, the commitment to eco-friendly practices remains a driving force in the development of automated packaging machines.

User-Friendly Interfaces: Simplifying Operation and Maintenance

In today's fast-paced manufacturing and e-commerce landscape, user-friendly interfaces are essential for streamlining operations and maintenance of automated packaging machines. A study from Smithers Pira indicates that over 50% of packaging line downtime is due to operator error. Incorporating intuitive interfaces can significantly reduce this factor, allowing operators to focus on production rather than troubleshooting. Additionally, machines equipped with touch-screen controls and real-time performance analytics empower users to monitor and adjust packaging processes with ease, enhancing overall efficiency.

To ensure effective use of automated packaging machines, companies should prioritize regular training sessions for their staff. Providing hands-on workshops can enhance familiarity with the user interface, ultimately minimizing errors and operational delays. Furthermore, leveraging visual aids and straightforward documentation significantly aids in the onboarding process and can foster quicker adaptation.

Another important aspect is the integration of visual indicators and prompts within the interface. These features not only guide users through complex tasks but also alert them to necessary maintenance checks. Companies implementing such proactive measures can achieve up to a 20% increase in operational uptime, according to research by the Association for Packaging and Processing Technologies, emphasizing the financial benefits of investing in user-centric designs.

Cost-Effectiveness: Reducing Waste and Maximizing ROI in Packaging Solutions

The packaging industry is experiencing a paradigm shift driven by the need for cost-effective solutions that minimize waste and maximize return on investment (ROI). Automated packaging machines are at the forefront of this evolution, incorporating innovative features designed to enhance efficiency and sustainability. These machines not only streamline the packaging process but also significantly reduce material waste through precise measurements and smart technology integration. As businesses focus on enhancing profitability, automated solutions that reduce operational costs become increasingly attractive.

The growth of reusable ecommerce packaging is another testament to this trend. With the global market for reusable packaging expected to soar, driven largely by the expansion of the ecommerce sector, businesses are seeking solutions that align with sustainability goals while being economically viable. By investing in automated packaging technologies, companies can capitalize on the trend of minimizing environmental impact while ensuring that they remain competitive. These innovations exemplify the intersection of cost-effectiveness and sustainability in packaging, ultimately fostering a more responsible approach to resource use within the industry.

10 Innovative Features of the Best Automated Packaging Machine - Cost-Effectiveness: Reducing Waste and Maximizing ROI in Packaging Solutions

| Feature | Description | Benefit | Potential Savings (%) |

|---|---|---|---|

| Smart Sensors | Sensors that detect package dimensions | Reduces material use | 15% |

| Automated Size Adjustment | Automatically adjusts to package size | Increases efficiency | 10% |

| Data Analytics | Real-time data monitoring | Identifies inefficiencies | 20% |

| Energy Efficiency | Utilizes power-saving modes | Lowers utility costs | 25% |

| Eco-Friendly Materials | Uses recyclable packaging materials | Reduces carbon footprint | 30% |

| Modular Design | Components can be easily upgraded | Extends equipment lifespan | 18% |

| Integrated Quality Control | Automatic inspection during packaging | Fewer defective products | 12% |

| User-Friendly Interface | Intuitive controls for operators | Reduces training time | 5% |

| Remote Monitoring | Access machinery data remotely | Improves response time | 8% |

| Robust Safety Features | Built-in safety mechanisms | Minimizes workplace accidents | Variable |